Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Notícias

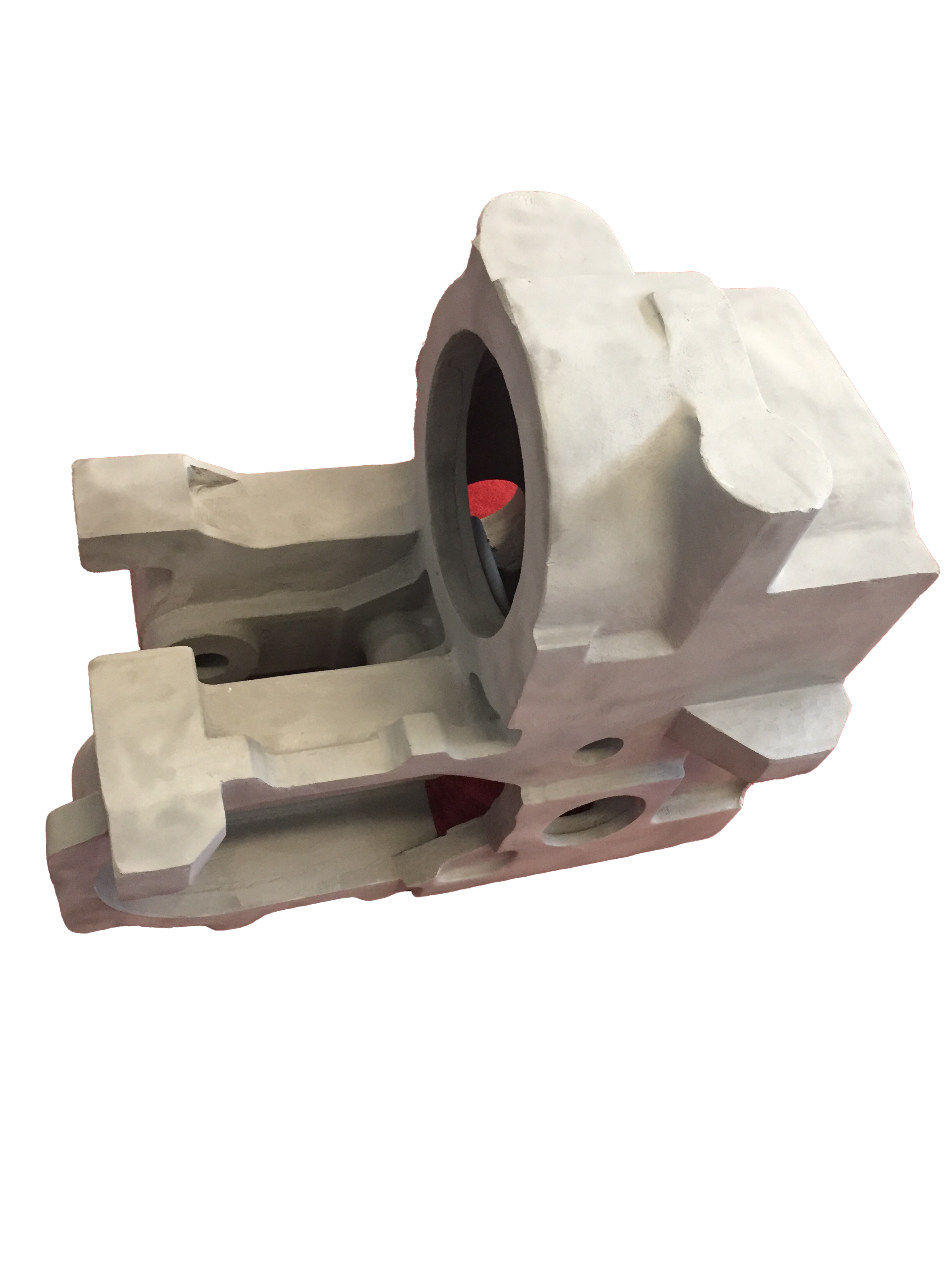

The Process of Forming Aluminum Alloy Die Castings

Aluminum alloy casting is a kind of pressure forging part. It uses a pressure casting mechanical aluminum alloy die-casting machine equipped with a cast iron mold. Alloy die-casting machine uses aluminum alloy die-casting to cast aluminum parts or aluminum profile parts with the shape and specifications of the mold. Such parts are generally called aluminum alloy casting.

The process of forming aluminum alloy die castings

Temperature is the main reason that affects the gradual forming of aluminum alloys, so how to control the temperature very well? Our stronger manipulation puzzle. We will introduce the difference between the temperature and casting parts of aluminum alloy die-casting production and processing in detail, and look forward to giving you some references.

The difference between the temperature of aluminum alloy die-casting production and processing and the casting

There are many reasons for this kind of situation. Among them, there will be poor structure of the casting; too early mold release, the rigidity of the casting is insufficient; It is easy to deform; part of the surface is not smooth, resulting in large friction resistance, and the product deforms during injection; the temperature of the abrasive part is too high, the product is not completely dry, the force during injection is large, or the small chain is not properly set, and it will withstand the pressure during injection. Uneven force; resulting in product deformation.

A special forging method that has developed rapidly in the laser cutting process of modern metal materials is working pressure forging. It is the whole process of filling molten metal material into metal mold under high pressure and high speed and condensing crystals under high pressure to produce castings. The key feature of aluminum die casting is high pressure and high speed. The common working pressure is tens of Kpa, the filling rate (internal glue inlet rate) is about 16-80 m/s, and the time for filling the abrasive type with metal material liquid is very short, about 0.01-0.2 seconds.

Casting is a situation where the raw materials are melted at high temperature, become liquid and have a certain flowability, and then are introduced into the concave mold. The general concave mold is sand mold, metal material type, etc., which are refrigerated and formed after fluidity in the set concave mold. However, the roughness is generally very low, and most of them are used as rough embryos, which must be independently rough and deep processed in the future. Generally, pig iron is used as the raw material for casting.

Because the metal materials copper, zinc, aluminum and aluminum alloy profiles have very good flowability and ductility, and forging production and processing are forged in an aluminum die-casting machine with working pressure, aluminum alloy die-casting can make various comparisons. The complex appearance can also be made with high precision and smoothness, which greatly reduces the machining volume of castings and the forging capacity of metal material copper, zinc, aluminum or aluminum alloy profiles, which not only saves money power engineering, metal composite materials, also save labor costs; copper, zinc, aluminum and aluminum alloy profiles have high-quality heat transfer, smaller proportions and process performance; castings are widely used in every manufacturing industry .

Conclusion

For more information about material used for die casting,aluminum die casting alloys,die casting engine block, we are glad to answer for you.