Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

resetAccountPassword

forTheAccount

pwdLetterLimtTip

inconsistentPwd

resetSuccess

resetSuccessTips

login

Notícias

4 & 5 axis cnc machining services

2022-05-10 17:43:45

For CNC aluminum machining, people always think of 5-axis CNC machining in the CNC machining service.

What is a CNC machining service?

CNC means computer numerical control, which manages the actions of different machine tools such as lathes and milling machines by using computers. The number of computers can be single or multiple.

What are 5-axis CNC machining services?

5 axis CNC machining services are an excellent way to machine aluminum parts. Can be used to precisely produce parts and final products from a variety of materials such as plastics and metals. Everyone's stereotype of 5-axis CNC machining may still be high-tech, expensive, and difficult to operate. However, this is not the case. Scroll to explore it.

Knowing the classification of machining centers will be more helpful for your understanding.

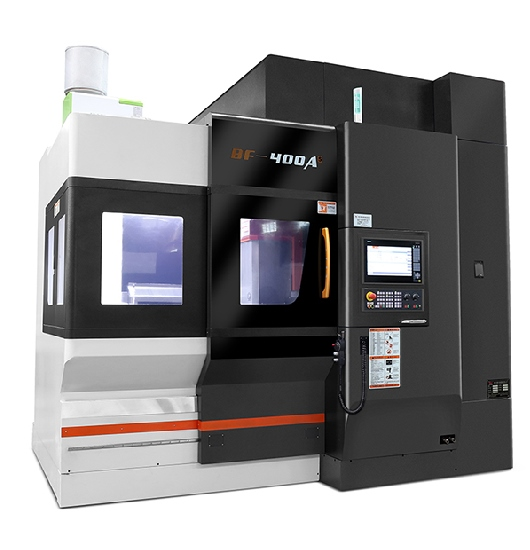

Classification of machining centers

Classification of machining centers

According to the spatial position of the spindle during machining, there are horizontal and vertical machining centers.

The spindle axis of a horizontal machining center is horizontal. It generally has 3-5 motion coordinate axes, and the common ones are three linear motion coordinate axes and one rotary motion coordinate axis (rotary table), which is the best choice for processing box-type workpieces. It has a more complex structure and higher quality than a vertical machining center, so the floor space and price are higher.

The axis of the main shaft of the vertical machining center is vertical, its structure is mostly fixed column type, and the worktable is a cross slide, which is suitable for processing disc parts. Axis CNC turntable (4th axis) to machine helical parts. It has the characteristics of simple structure, small footprint, and low price, and can be used for most workpiece processing after being equipped with various accessories.

For large gantry machining centers, the main shaft is mostly vertical, especially for large or complex workpieces. These multi-coordinate gantry machining centers are required for the processing of certain parts in the aviation, aerospace industry, and large steam turbines.

The five-sided machining center combines the functions of the vertical and horizontal machining centers. After the workpiece is clamped once, it can complete the processing of all five surfaces except the mounting surface, so that the shape error of the workpiece is minimized, eliminating the need for two can improve production efficiency and reduce processing costs.

To sum up, the operation of 5 axis CNC machining service is simple and cost-effective and includes the functions of vertical and horizontal machining centers. The accuracy of workpiece shape is very high, which greatly improves production efficiency and reduces processing costs.

Difference between 5 axes and 4 axis CNC machining service

4 Axis CNC machining: Three linear motions in different directions can be added by adding another axis of rotation. In addition, it can rotate 360 in the horizontal plane (not tell rotation) and can machine part of the box parts.

5 axis CNC machining: There is one more rotation axis on the four-axis, usually the vertical surface rotates 360°. It can realize one-time clamping, and reduce the cost of clamping as well as product scratches and bumps. It is suitable for machining some multi-station pores and planes, and parts with high machining accuracy requirements, especially parts with strict shape machining accuracy requirements.

Conclusion

If you need high-precision parts, it is recommended that 5-axis machining services. Although the advantages of the 5 axes compared to the 4 axes are very prominent, not all products are suitable for five-axis machining, and those suitable for four-axis machining are not necessarily suitable for five-axis machining. Not only will it increase the cost, but the effect is not necessarily good.

Only by using a suitable machine tool for the product, can the value of the machine itself be brought into play. If you are looking for 4 & 5-axis CNC machining services, please contact Minghe.

Contate-Nos